Hi all,

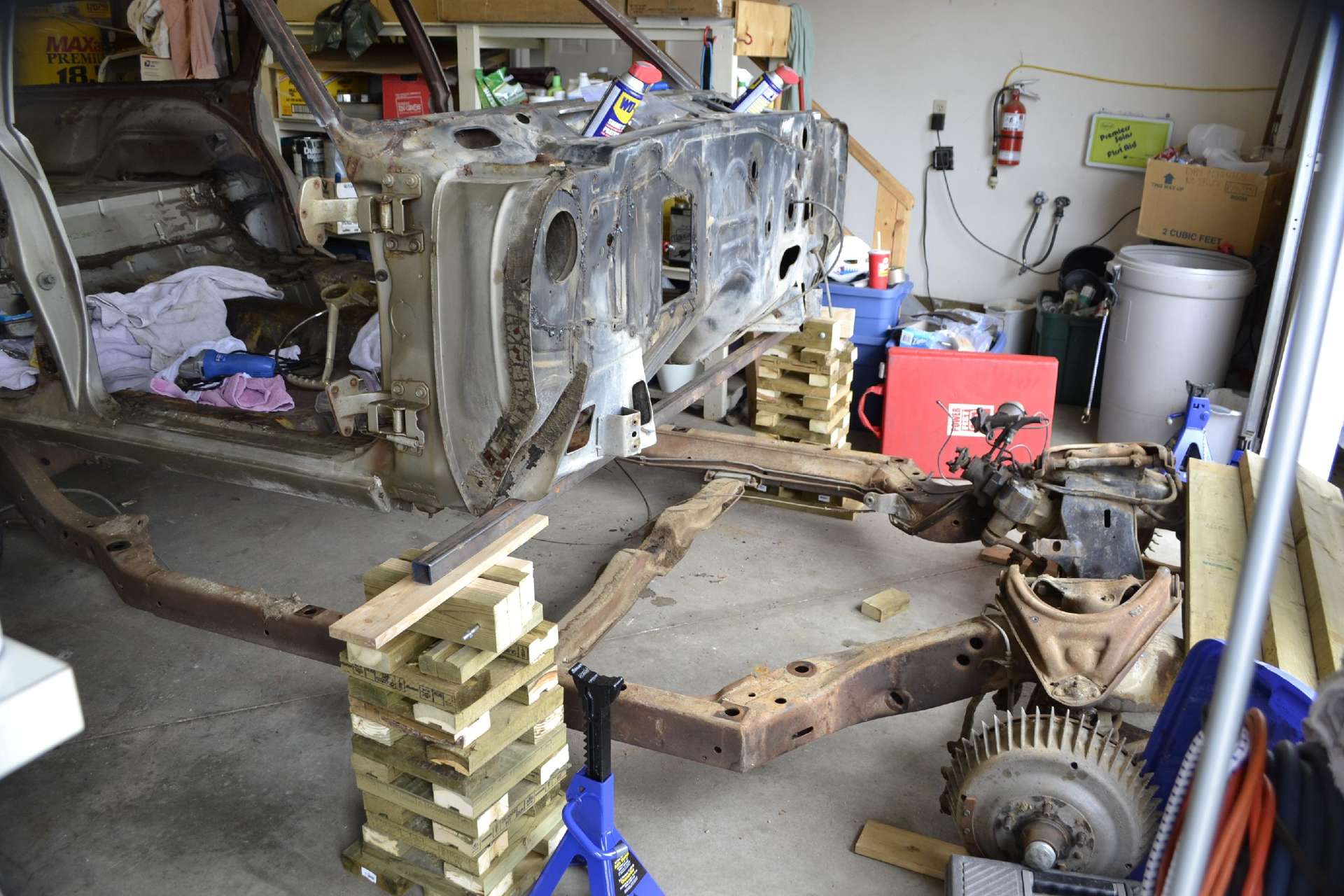

I'm about to tackle the rear now and will be removing the gas tank, leafs, shocks and exhaust system. I plan to do a lot of wire brushing, cutting, welding and shoving. I want to be sure that she's a solid as possible when off the concrete by about 2 feet, so I'll be mainly relying on blocked-up jack stands on the four key points, but want more than just that. Any other good sturdy ideas that have made you more comfortable under there?

To start with, if you put jack stands on top of anything other than sometime bolted down to the floor your gonna die on us. Jack stands on blocks is an easy way to hurt and possibly kill you.

The are good reasons for why jack stands (typical ones you buy at a popular store front) are limited in height. Some of you guys are Engineers and took a Statics course and you the calcs that prove the instability of jack stands given the diameter of the base of the jack stand.

I won't get into the calcs but understand that the higher you go up on a jack stand the more unstable it becomes. The mechanical advantage (lever) increases with height of stand. For example, if you push the car horizontally with a jack stand that is 3' high, it does not require as much force to tip it over. It's like putting a 3 foot metal pipe on the end of you socket wrench.

So if you want to go high you have to purchase much larger stands to handle that height. Stands will be higher (static lowered height) and the base diameter will be much larger. The increased size of the base is what allows you to go higher.

You can do a few things to make the common smaller stands work higher, but it's risky when you are battling with the car.

I will give you some options you can think about.

1st, you can build it in wood or steel. If you know more about wood than steel then consider using wood. Obviously steel could be used as well.

Option #1 Wooden blocks stacted (6" x 6")

Option #2 Wooden or steel cart (lots of plans out there for these. Requires welding for steel but I have a wooden cart that will hold a heavy car shell (no drive trane), easy to build

Option #3 Special steel cart that can be configured to be used by a range of cars. Height, width and length adjustable.

Option #4 Hydraulic hoist to lift car up. Limited on what you can do with this design.

Work smart, do your research in advance (like your doing now). BUY GOOD tools! Tools can make difficult job fun and rewarding. Save money by working smarter and buying good tools. Remember, when your done your project you can sell your tools and recover at least 50% of your investment. I bought a paint gun for $500 US. The quality is amazing. They retail at $1000. How much do you think I could get back for a one car use of a SATA paint gun? You save nothing buying crap. 3 paint guns, one price, products are cash cows for the distributor but useless for you. They are good for a couple of sprays and then they are done. Worth $0! And they suck as far as quality goes.

Get your self 2 good trolley jacks as well. Get them from COSTCO, they go bad 5 years later, you can take em back for refund or get another new one.

I can send you some picks of this stuff. Let me know what your interested in.

One last thing...a guy came onto the forum one day and chatted about how happy he was to be finished removing all the dirt, grease, paint off the underside of the car. He laid under the car with no stands, jack or anything. Used a scrapper, wire brush on a drill. Time is more important than cash. You can get more productivity out a plant increasing the no. people working there (many other things as well). You can go from 20/cars a day to 1000 cars/day. BUT you can't change the work day from 8 hours to 5000 hrs. God only gave us a 8 hr day. If you want more people hours (hr/day x no. of people) then hire more people. Back to our "hero" above; where do you start?

So I'm a little heaving on the spending (my project is stalled awaiting to get more time available to work on my project), try to find a balance you can leave with.